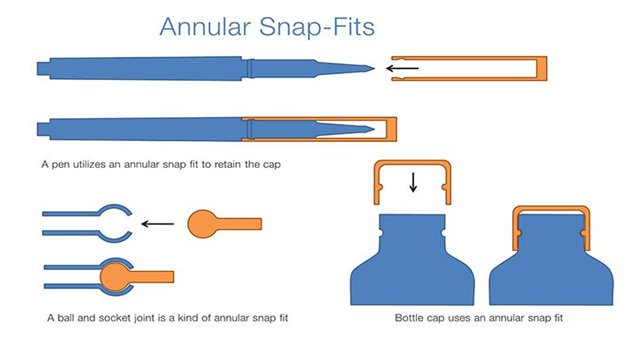

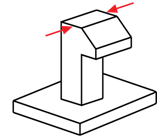

Annular snap-fits

- The annular snap-fit utilizes hoop-strain to hold a pressed part in place. Common examples of annular snap-fits are bottle and pen caps.

- With annular snap-fits, it is possible to achieve a waterproof seal around the joint.For the rest of this article, the focus will be on cantilever snap-fits.

In this joint the strength is more, and the locking mechanism is accurate for the complex designs.

Why to use annular snap-fit???

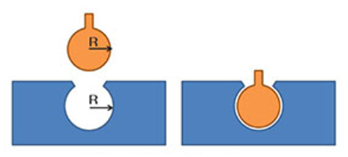

for very small snap fit designs which may introduce very thin sections, one might consider an alternative compressive type annular snap fit design. Compressive type snap fit designs are common in industry for high cyclic applications and/or can be used successfully with brittle materials when other types of designs prove difficult.

Designing snap-fit connections:

In general, snap-fits will encounter the most stress during attachment and should return to their neutral position once the joining process is completed.

● Once the parts are mated, an undercut holds them together. Depending on the shape of the undercut, snap-fit assemblies can also be designed to be permanent. A well designed snap-fit with suitable material can be used many times without any noticeable fatigue.

Good design practice:

Several design features can be implemented to reduce stress and strain on the snap-fit assembly. These include:

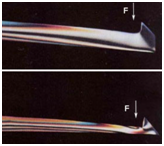

Taper the design:

A snap-fit cantilever with constant cross section has an uneven distribution of strain (top image).

A good design tip is to diminish the cross section of the cantilever beam over its length (bottom image). This uses less material and results in a more even distribution of strain in the cantilever.

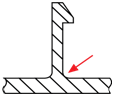

Filleting the base of the cantilever:

- The addition of a fillet at the base of the cantilever can help to distribute the stress over a broader area making the connection stronger.

- The radius of the fillet should be at least of 0.5x the thickness of the base of the cantilever.

Increase width:

- Increasing the width of the clip will add strength to the design (if this is feasible in the design constraints).

- This may require trial and error to achieve the correct stiffness however the clip should be at least 5mm wide.

Final position:

To help reduce stress and improve the strength of the connection ensure that the snap-fit cantilever is only deflected during the assembly and not when the components are connected together.